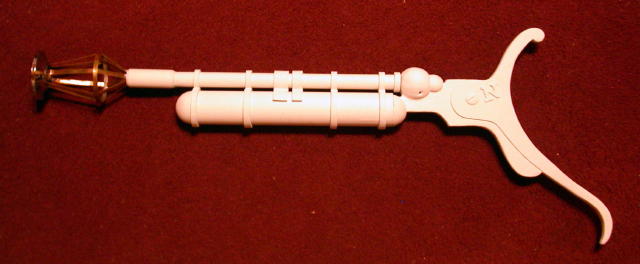

CHEAP NEMO RIFLE

Make your own replica Nemo rifle from inexpensive hardware store and craft shop parts.

I was organizing a photo dive involving our

NEMOSUIT and NAUTILUS DIVER rigs when it occurred to me I only had the one

metal NEMO rifle I’d built a couple years ago, and I needed another prop rifle

for the Crew Diver. I noodled it around

a little bit, and came up with one that I tossed together out of junk that was

laying around the shop, plus a couple small things I bought at the local

hardware store. It was cheap and

easy. I used the prototype as a “plug”

from which sand-cast prop rifles were made out of aluminum for use underwater.

Then I thought about all the people over the

years who’ve said they wished they had a replica of the Underwater Rifle. So here’s how to make a replica Nemo rifle

out of scraps you may have on hand, and a few inexpensive odds and ends.

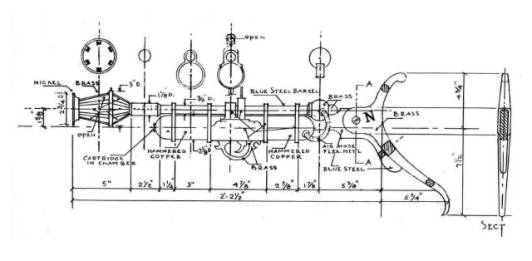

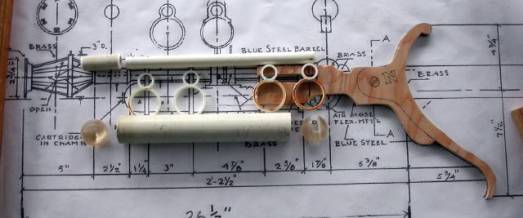

(1)

The first thing you need to do is download a picture of the plans. Here’s a link: UWR

PLANS. Save and print the image

on an 8- ½” X 11” piece of paper, and take that to your local blueprint shop to

be enlarged until the dimensions match.

Now you have a set of 1:1 scale working plans on paper.

Disney

Underwater Rifle plans.

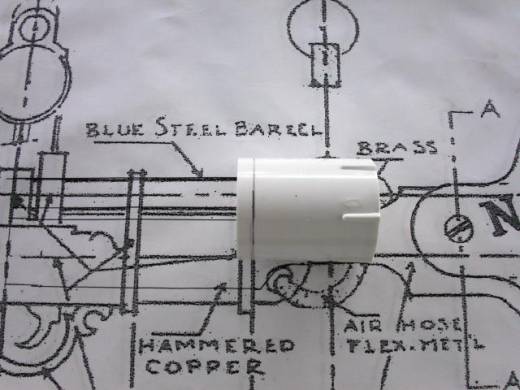

(2) Acquire some PVC tube: ½” for

the barrel; ¾” for the muzzle brake; and 1-1/2” for the tank cylinder. (That’s just a fraction thin for the

tank, but nobody ever noticed.)

You’ll also need some hemispherical end caps: I used those little

two-part plastic ornaments they sell in craft stores as a mold to cast acrylic

parts with. Like so:

(3)

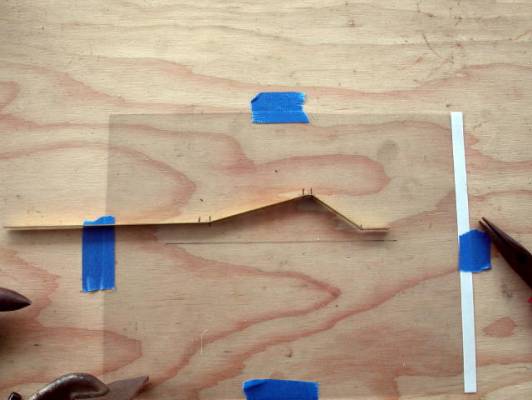

Trace the plans onto some posterboard or cardpaper to make a template for a

rifle stock and frame that looks something like this. (The straight pieces must fit snugly inside the PVC tubes.) Then trace that image onto a piece of ¾ inch

plywood. (It could be thicker, but

that’s what I used.)

(4)

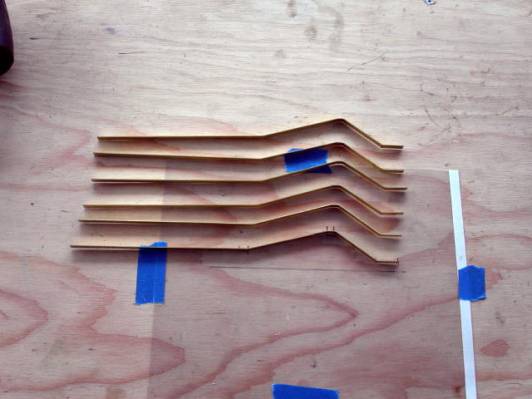

Cut the pattern out with a scrolling saw.

(5)

Do a little sanding, and slip the parts together thusly.

(6) Next, get some PVC slip couplers and mark

them the thickness of the Figure-8 clamps.

You’ll need two sizes: 1-1/2” for the tank and ½” for the barrel. Mark them relative to the plans, like so:

(7) I used a 4” Makita grinder and thin cutoff

wheel. What I ended up with looked like

this:

(8) Slip

fit them side-by-side as below to mark the over lap with a pencil; then trim so

they fit together.

(9)

Grind notches (Dremmel) and glue the pieces with PVC cement so you end up with

four Figure-8 clamps that look like this:

(10) Next: tape the plastic ornament

hemispheres (or plastic ball halves, or whatever you’re using) on the

ends of the tank tube like this. Be

sure to coat the inside of the tube and hemisphere with wax or mold release

first.

(11) Pour in clear acrylic casting resin in

from the opposite end, (one end at a time) and let harden. Pull each plug and strip off the plastic hemisphere,

to make two acrylic tank cap “plugs” like this:

(12) Next, the parts for the muzzle cage are

brass strips from the local Ace hardware store. I bought seven. Very

inexpensive.

(13) To make the ring, I bent the brass strip

into a hardware fixture; you could use something else as long as it was the

right size. Then, a touch of the torch

and bit of brazing rod was all it took to get it to look like this.

(14) Next, I traced the contour of the cage spokes

from the plans onto a sheet of clear mylar, and used it as a guide to bend

against. I just grabbed them with a

sheet metal vice grip and bent them by hand until they fit. There was a lot of variation in the actual

guns seen in the movie, so you don’t have to be exact here.

(15) Make

six “spokes”. They should all pretty

much fit together like this:

(16)

I drew a diagram on graph paper to make sure I marked the ring evenly in

60-degree increments. I used short

pieces of copper tube: 1” for the front and ½” for the rear muzzle rings. The hardest part was getting it all clamped

up and straight before soldering. Be

patient.

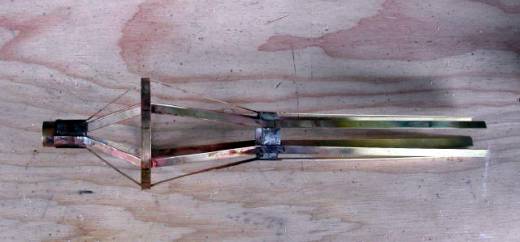

(17)

After soldering, it looked like this:

(18) After reeming out a little PVC, I’ve got it

test-fit to the “muzzle brake” tube.

(19)

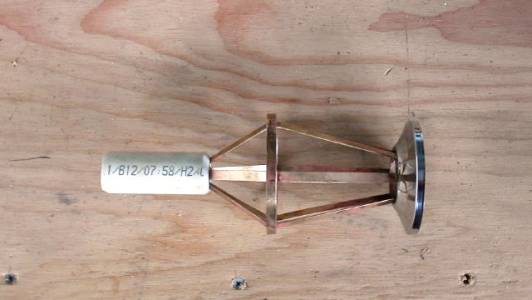

The muzzle flare is a common plumbing pipe trim piece from the hardware store.

(20)

After the cage is trimmed and test fit, it looks like this:

(21) Notch the aft Tank Cap to fit the

frame. For the two Breech Spheres you

could use small (1-3/4” and 1”) wooden balls from the craftstore: cut out a

notch so they fit the frame and epoxy them together. Instead, I just made these out of two-part plumbers epoxy putty:

rolled into a ball, cut a notch with a knife, and fit to the frame by hand

while it was still pliable. I poked in

a hole with a nail for the stud on which I’ll attach the air tube. A little sanding improved the Sphere’s shape

after the epoxy hardened. Also at this

time, the two center 8 clamps are made the same as the others only wider, and

will be trimmed later to fit the Trigger Assembly plate. Slip fit it all together and it looks like

this so far.

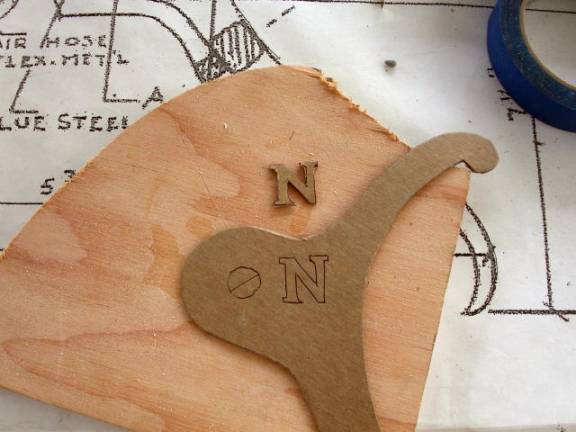

(22) All I did to make the buttstock bolsters

and the “N” was trace and cut them out of thick cardboard. You could use thin modeler’s plywood; but

coated with epoxy, cardboard is good enough, and it’s easier to work with. I made the faux screw slot head out of

plumber’s epoxy putty and superglued it on.

(23)

At this point I painted it with flat white plastic primer to see how it was

shaping up.

(24) The trigger and guard are drilled / cut

from plywood with a little extra carving and sanding. The tank wrap is thick cardboard. It’s epoxied together with a Popsicle stick inside for strength;

and I put on a Popsicle stick for trim because I wanted a little additional

detail there.

(25) Drill six holes in the Muzzle Brake

tube, fill in the front of the muzzle flare with Bondo or a suitable piece of sheetmetal,

add little more primer, and there ya go.

Ready to paint.

So that’s the basic gun, finished to the point where you

could use it as a casting plug to make copies if you want to. (Take the muzzle cage off first, of

course.) I’d recommend a coat of liquid

epoxy or several coats of gloss paint to make it slick. And then use some good mold release.

Or, if you just want to finish this one:

drill a hole in the aft tank cap, and epoxy in two short pieces of nail on

which to attach your air tube from the tank to the spherical breech

chamber.

The plans call for a thing called the

“cartridge” at the front of the tank; some of the prop rifles have what looks

like a tire inflator valve there. I

didn’t bother with that for these rifles, but if you wanted to add those

details it wouldn’t be difficult.

If you want to put on the sights, they are

easily made. (I didn’t do that because

I know from experience it’s just one more thing to get snagged underwater; and

you never use them when you shoot a gun like this anyway: especially

when you’re wearing a 20,000 Leagues diving helmet.)

But if you want the sights, it’s basically a

piece of flat scrap with a peep hole in it, glued atop the barrel above the

trigger; and the front blade is the collar from a pop rivet soldered to the

muzzle cage. (Refer to the plans for

details and placement.)

I made this gun from junk I had laying around the shop, plus

a couple inexpensive things I bought at the hardware store. Total cash outlay for mine was about

$25. Yours might be a bit more or less,

but you should be able to make one of these without spending a lot of money,

and have a lot of fun doing it. And

when it’s all done and painted correctly, it will look great hanging on the

wall above your Nautilus model. ![]()

HOME PREVIOUS NEXT